Imagine your family has driven to a local lake to cool off. On this hot day, the sun is scorching, but sweet relief is just seconds away. You’re sprinting to the end of the dock, about to jump — when your parents suddenly yell, “Stop!”

Skidding to a halt, you turn to see a park ranger hammering a sign into the sand: “NO SWIMMING — WATER CONTAMINATED.”

When water leaks from sewage pipes or washes off farmland into waterways, it can carry human and animal poop with it. Riddled with germs, that waste can make you sick. Fortunately, tests can quickly detect DNA from animal wastes in that water.

And key to the accuracy of these tests is having a good “standard” reference material, or SRM, against which other things can be matched.

Stephanie Servetas was on the team that developed an SRM for DNA detectors. They dubbed their group the “Poop Team,” she says. A microbiologist, Servetas works at the National Institute of Standards and Technology (NIST). Its headquarters is in Gaithersburg, Md.

Her Poop Team’s reference material contains bits of DNA that match wastes from people, cattle, pigs and other animals. The team mixed and measured their concoction’s properties precisely. That way, they can say exactly what values water-testing instruments should register to signify they found poop.

Water watchers anywhere can now use this material to check that their machines are working correctly.

Labs that run blood tests make sure their machines are up to snuff using other NIST materials — such as standards for vitamin D and cholesterol. Kibble companies use standard dry cat food to ensure each bag they produce contains the stated nutrients for our furry friends. Even automakers rely on NIST-certified steel to confirm a car’s metal bits have the right properties.

In a sense, these SRMs are the so-called “gold standards” for things. They’re the benchmarks against which all materials of some type should measure up.

Each SRM sample comes with lots of data on its properties — data which NIST measures more accurately than almost any other lab can. “I call it truth in a bottle,” says Steven Choquette. He directs the Office of Reference Materials at NIST. His lab provides more than 1,100 types of SRMs.

This bizarre collection is housed on heavy-duty shelves in a huge warehouse in Maryland. Think of it as a library. As you wander through its aisles, you might see some labels familiar from your grocery store. There’s peanut butter and soy milk. Other holdings here won’t be found anywhere else — like “urban dust” and “trace metals in frozen human blood.”

At a glance, these SRMs may seem random. But they’re not. Each was carefully chosen and crafted to solve a serious problem or to support an important new technology.

Let’s look at some of the most surprising, widely used and cutting-edge additions to NIST’s weird library. Some might just save your life.

Number one in number two

The fecal DNA used for water testing isn’t the only reference material Servetas’ Poop Team worked on. Earlier this year, it debuted an official sample of human poo. Sound gross? Well, don’t turn up your nose. Experts think it will be a game-changer for monitoring health and diagnosing disease.

Our digestive tract is full of microbes. Scientists refer to the mix as our gut microbiome. Some of these microbes attach and move with food as it travels through the body, eventually exiting in feces. Our gut’s microbiome offers clues to what’s been going on inside us. For instance, those microbes affect how our bodies fight infection and cancer. Some of those microbes could be the missing link that explains why exercising boosts our mood.

And getting some poo is much easier than trying to sample these microbes while they’re in the gut.

Some patients are already asking doctors how their gut microbes compare to a “healthy” set. But answering that would be challenging, says Diane Hoffmann. She studies healthcare law at the University of Maryland in College Park. That would be like “classifying all the kinds of straw,” she says, then “counting all the straw in a haystack.”

Such tests would have to measure how many types of microbes you have and the rough numbers of each. That would require very high accuracy. Right now, such testing just isn’t accurate enough to take a good census of someone’s gut microbes.

Plus, scientists today have only a loose understanding of how microbiome data relate to our health. Having an official set of human feces for comparison might one day make analyses of our poop less murky.

The microbiomes of vegans and vegetarians differ from those of people who eat meat. So Servetas and her colleagues created two standard number twos. One is from vegans, the other from omnivores.

For each, the researchers blended donated feces with dry ice. Then they filtered the mix, combined it with water and stored it at -80° Celsius (-112° Fahrenheit).

Does it still resemble poop? “Not so much,” Servetas says. But it now allows different stool-analysis labs to compare data and interpret what they find. These are key steps for figuring out which microbes should be living in our gut and which might cause problems. That might pave the way to microbiome tests that one day guide health and medical decisions.

Food, glorious food

Standard poop may help us track what comes out of our bodies. Another set of materials helps measure what goes in.

NIST has a whole mini-mart of SRMs for food. Manufacturers use these to make sure their measurement equipment is accurate. That’s how they put together nutrition labels that can tell you exactly how many grams of protein are in your peanut butter. Or whether your apple juice contains arsenic.

These labels help people look for the nutrients they need and help manufacturers (and diners) avoid ingredients that might make them sick.

NIST scientists have developed more than 30 different standard reference foods. That might not seem like enough to accurately label the thousands of products in grocery stores. But food manufacturers don’t need to test their instruments on the exact foods they’re making. They can just use the food with the closest nutrient profile.

Here’s one surprising match: spaghetti sauce and infant formula.

A sauce maker can use standard infant formula to check that their machines are well calibrated to take data accurately. If so, those machines are ready to measure nutritional info for the sauce, too. The foods definitely aren’t interchangeable on your plate. But the nutrient results they now spit out will be pretty spot on!

Of course, plenty of stuff can wind up in our food that isn’t listed on the label. Molds that grow on peanut crops can produce a poison (aflatoxin) that ends up in peanut butter. As spinach grows, it can soak up the heavy metal lead from soil. When livestock get exposed in the environment to pollutants called PFAS, those chemicals can end up tainting meat.

These contaminants are dangerous. So NIST has been developing food SRMs with known amounts of toxic materials, such as PFAS. Once food companies tune their machines using such SRMs, they can now accurately measure contaminants in our food supply — even in small amounts.

Especially when it comes to food allergies, small amounts can have big consequences. That’s why NIST developed standard references for each of the eight main categories of food allergens: milk, egg, wheat, soy, peanuts, fish, shellfish and tree nuts. The U.S. Food and Drug Administration requires that food labels must list whether they contain these allergens (or might contain them due to cross-contamination on farms or in factories).

Heavy metal science

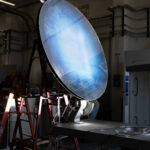

Move along to the hardware aisle and you’ll find something called a Charpy. This small, rectangular piece of steel with a V-shaped notch in the middle might not look like a big deal. But these metal bits are NIST’s most popular reference material — and for good reason. They help prevent many types of disasters.

To imagine how, just consider the Titanic. In 1998, scientists at NIST examined pieces of the sunken ship that were hauled up from the bottom of the icy North Atlantic Ocean. Their findings were chilling: The Titanic’s steel lacked the right properties for shipbuilding.

When the Titanic smashed into an iceberg in 1912, rivets holding together the boat’s hull popped apart. Why? They hosted too much slag, a byproduct of steelmaking. That slag impurity made the rivets brittle at cold temperatures. And when they broke, ocean water gushed into the ship’s hull.

With proper steel testing, catastrophes like the Titanic’s sinking can be prevented. The “Charpy test” is a simple but powerful way to see whether a batch of metal is “good” or “no good” for building things such as ships, skyscrapers and even nuclear reactors.

How do you test the toughness of metal? Hit it hard.

To run the test, you need a Charpy machine. This device has a massive pendulum that swings down from a set height and — wham! — hits a Charpy right on its notch. That snaps the Charpy in half. The pendulum doesn’t swing as high after the collision. The difference between the starting and ending heights shows how much energy it took to break the Charpy. This is the metal’s “impact toughness.”

The impact toughness of each NIST Charpy is precisely known. So metal producers use them to confirm their Charpy machines are working well. This can “verify that the machine keeps providing reliable results,” says Enrico Lucon. He leads NIST’s Charpy Machine Verification Program. “They can even tell from marks on [a Charpy] what parts of the machine might need maintenance.”

Metal-makers around the world use NIST Charpy specimens to ensure their metals are sturdy enough to hold up bridges and buildings and to prevent other titanic catastrophes.

Do you have a science question? We can help!

Submit your question here, and we might answer it an upcoming issue of Science News Explores

Burning questions

For smaller-scale disasters, standard cigarettes play a perhaps surprising role in keeping us safe. NIST’s cigarettes aren’t for the tobacco industry. Their purpose: fire prevention.

Most fatal house fires in the United States start with cigarettes. Back in the 1980s and ‘90s, the problem was particularly bad. The government and fire experts wanted to know how to bring the death toll down. So NIST scientists investigated. They discovered that both cigarettes and furniture play a role in whether a fire ignites. That led to the development of two standard reference cigarettes.

The first one looks and acts like an ordinary cigarette. It has thin bands in the paper that are less flammable. They slow the burning of a lit but unattended cigarette. That’s a safety feature. Some states have passed laws saying that if a cigarette burns faster than the NIST standard, it can’t be sold.

The second type of standard cigarette is for testing furniture. “I call them road flares,” said Rick Davis. “They’re intended to burn — and burn intensely,” explains this materials-science engineer. He leads NIST’s Fire Research Division.

It’s important that this cigarette is good at lighting fires. Say a mattress is tested with a cigarette that doesn’t burn well. The mattress might pass as fire-safe, even if it would go up in flames with a faster-burning cigarette. Today, all mattresses sold in the United States must pass tests using the NIST “road flare” cigarette.

Has flammability testing saved lives? Almost certainly. The United States has nearly halved its rate of fire deaths since 1980. But Davis warns against giving too much credit to standard cigarettes. “You have to be careful with fire statistics,” he says. A lot of other things have changed, too. For one, fewer people now smoke cigarettes.

Still, smoking remains the leading cause of U.S. house-fire fatalities. And most of those fires still start in a living room or bedroom — making standard cigarettes and their flammability tests as important as ever.

It’s alive!

Pop your head into the freezer section of the SRM library at NIST to find one of its newest items. It’s a soup of cells called NISTCHO. It’s the first living reference material.

NISTCHO cells produce a protein called a monoclonal antibody, or a “mAb” for short. From a single vial of NISTCHO, scientists can grow 200 times more cells, says NIST biologist Megan Cleveland. It’s like giving a lab its own little mAb factory.

Why is that useful? Since mAbs were discovered in 1975, these molecules have opened up a new world of treatment options for cancer, asthma and other diseases.

You need living cells to make mAbs, says Michael Tarlov. He leads the Biomolecular Measurement Division at NIST. These proteins are thousands of times bigger — and more complex — than “small molecule” drugs such as ibuprofen. And the way mAbs work in the body depends on how they’re made. That includes everything from how the cells are grown to how the mAb is purified.

Wrangling living cells is no easy feat. It’s not possible to control every detail in the long mAB-making process. NIST made its mAb standards factory to help. Certain tests are vital to check that mAbs have the right properties to be safe and to fight disease. Now researchers can test the mAbs they make against those produced by NISTCHO cells to confirm they’re getting accurate results.

What’s next?

NIST is developing new SRMs all the time.

One team is currently working on a reference material for diagnosing mpox, an illness caused by what was formerly known as the monkeypox virus. Another SRM in the works would aid forensic DNA testing. Samples collected by law enforcement, including the FBI, often contain the DNA of more than one person. That DNA may be damaged, or “degraded.” NIST is working to help forensic scientists interpret tests on such less-than-perfect DNA samples.

These works-in-progress are called “research-grade test materials.” They haven’t yet reached Choquette’s “truth in a bottle” status. But each aims to one day help people accurately measure new things.

Not all research-grade test materials will reach the shelves of NIST’s warehouse of standards. Sometimes, it’s impossible to make something that performs the same way every time it’s tested, is easy to handle or has a long shelf life. But when a new reference material is born, the world becomes safer, healthier and more productive — one ultra-precise measurement at a time.